Auro Lamp

This five-week project focused on designing the Auro Lamp, beginning with mood boards and a defined setting to guide its aesthetic and functional direction. Through iterative form exploration, 3D modeling, and 3D printing, the design evolved to accommodate internal electronic components while maintaining a clean, cohesive exterior. The final prototype demonstrates a balance between technical constraints and refined visual design.

Design Goals

Defining the Objectives of the Project

Hide internal parts without disrupting the lamp’s clean form.

Arrange components to keep the design simple and uncluttered.

Match the lamp’s style to the chosen mood board.

Use consistent shapes and details to create a unified look.

Place controls where users naturally reach.

Make interaction simple, clear, and easy to understand.

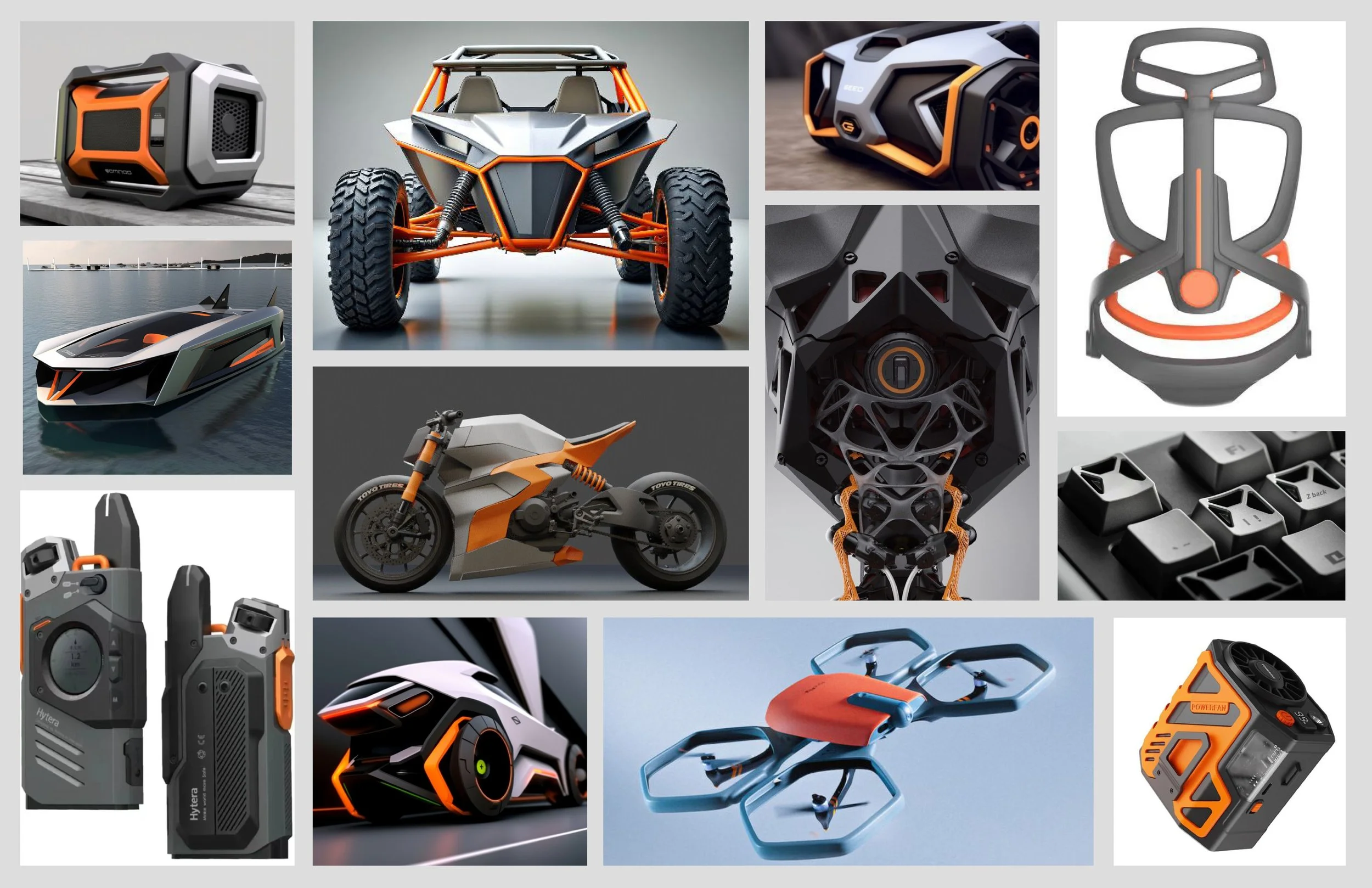

Mood Board

Highlighted geometric shapes and strong industrial frameworks

Pulled inspiration from vehicle chassis and exposed structures

Explored futuristic and robotic visual cues for form direction

Focused on rigid lines, clean surfaces, and structural clarity

Established an industrial, tech-forward aesthetic foundation for ideation

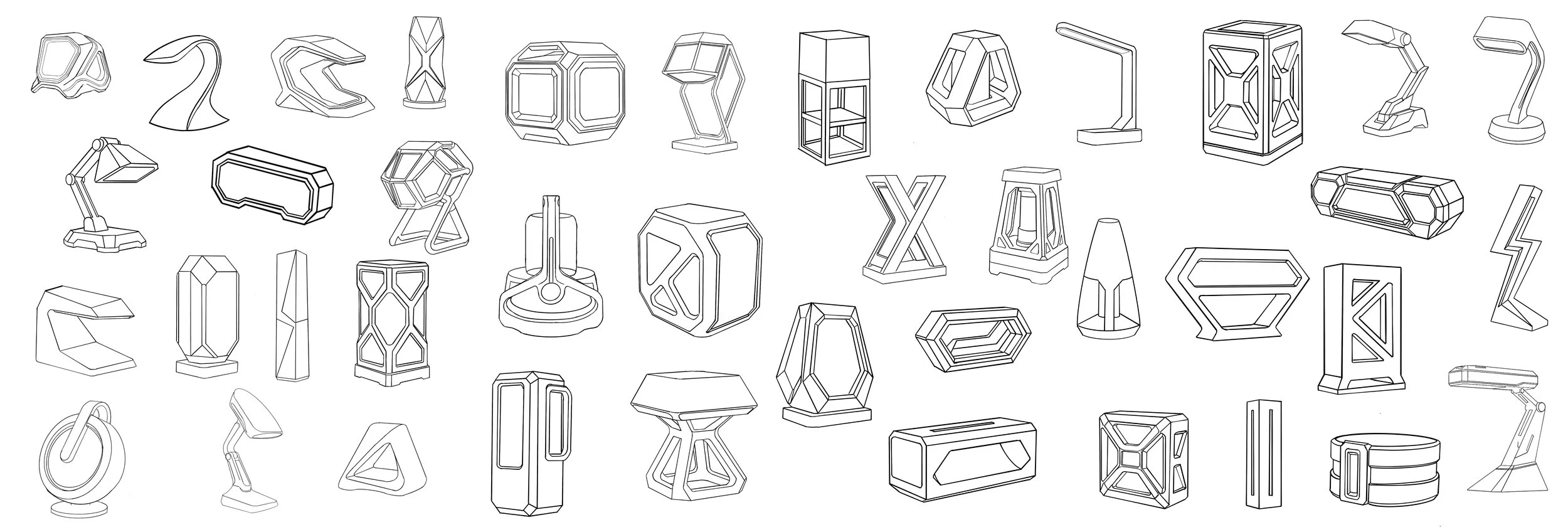

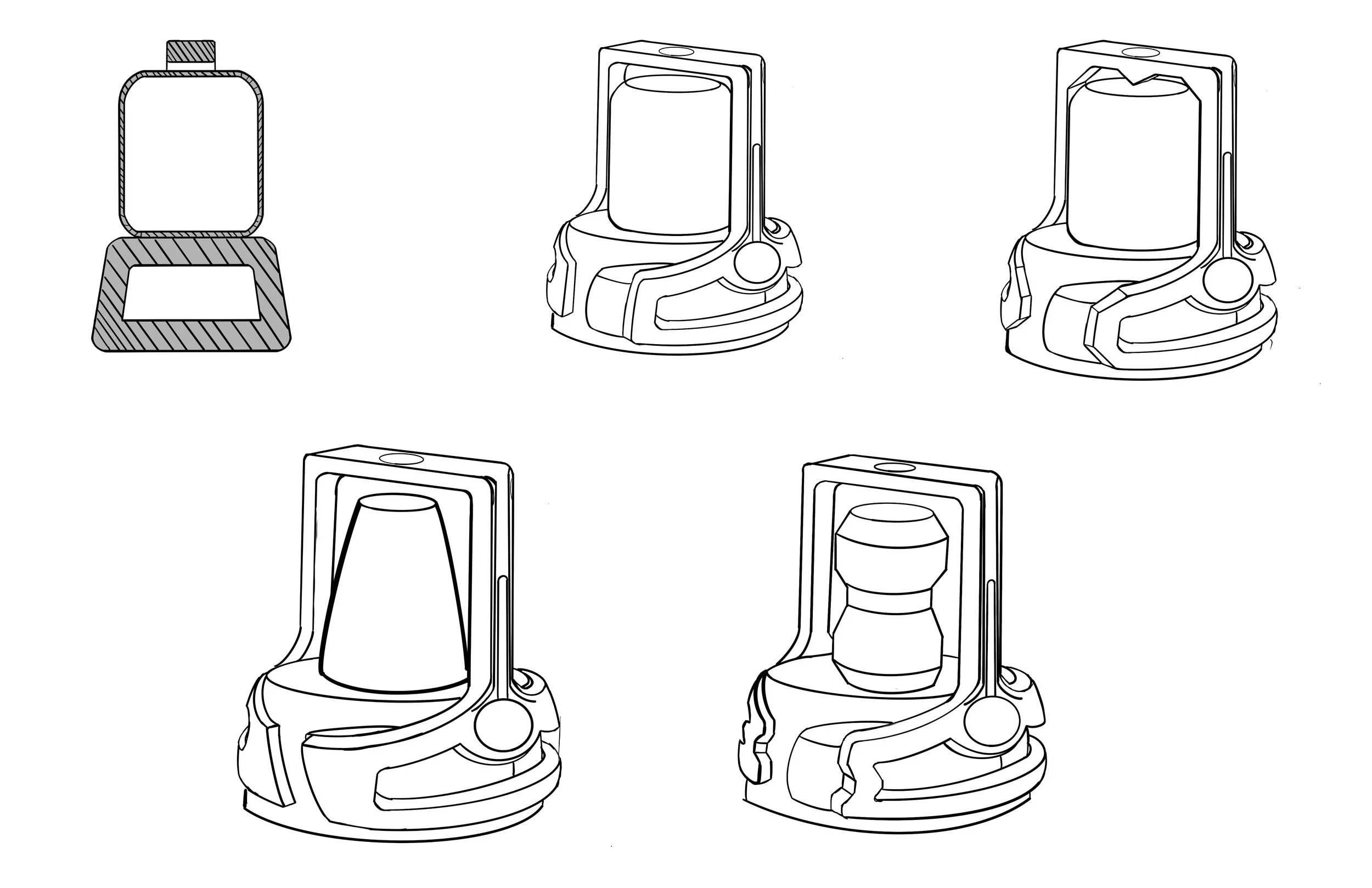

Ideation Sketches

Early Concepts Driven by Mood Board

Explored geometric forms inspired by industrial and robotic frameworks

Sketched futuristic silhouettes built from clean structural shapes

Combined rigid frames with tech-forward details for early concepts

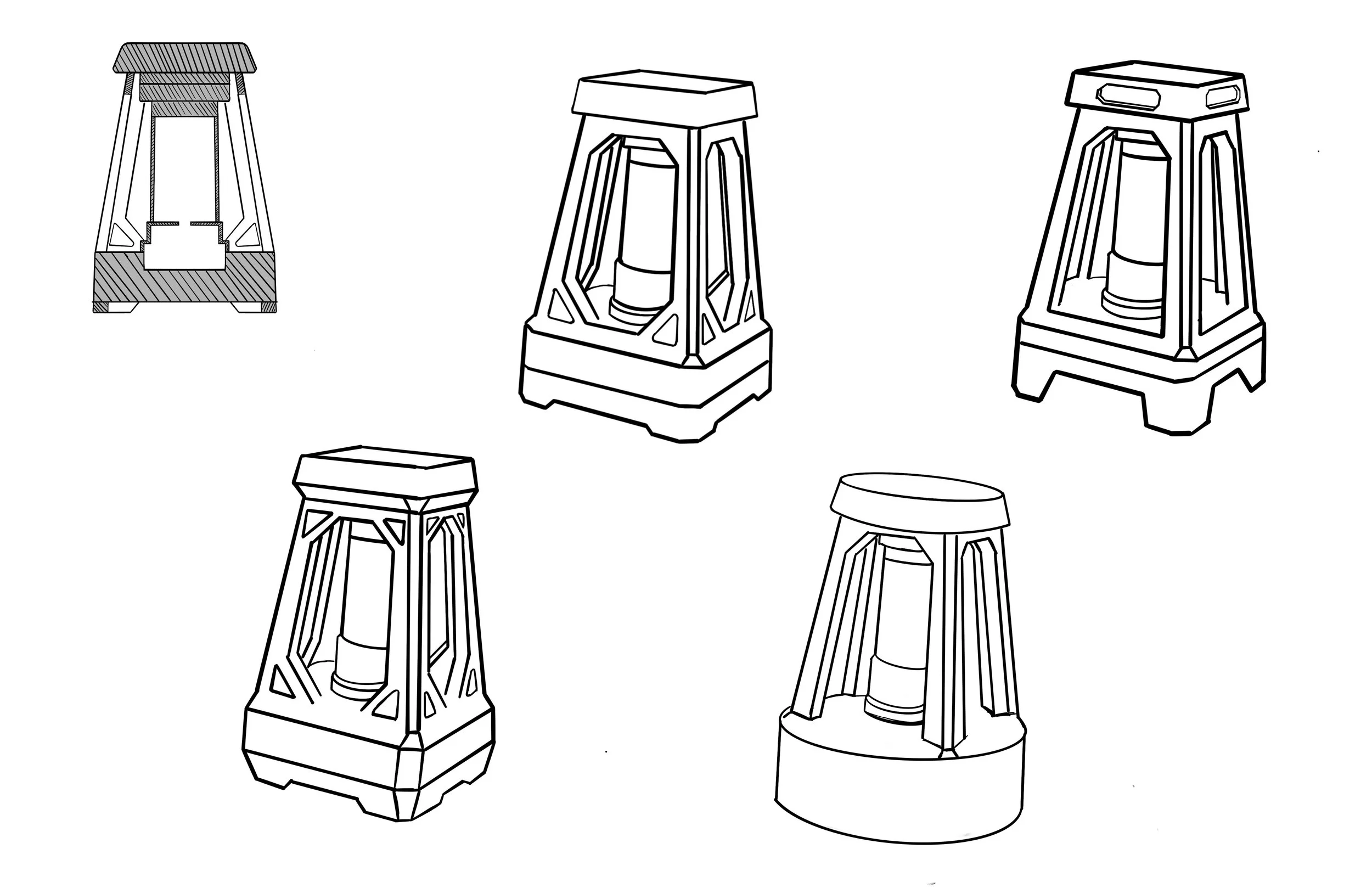

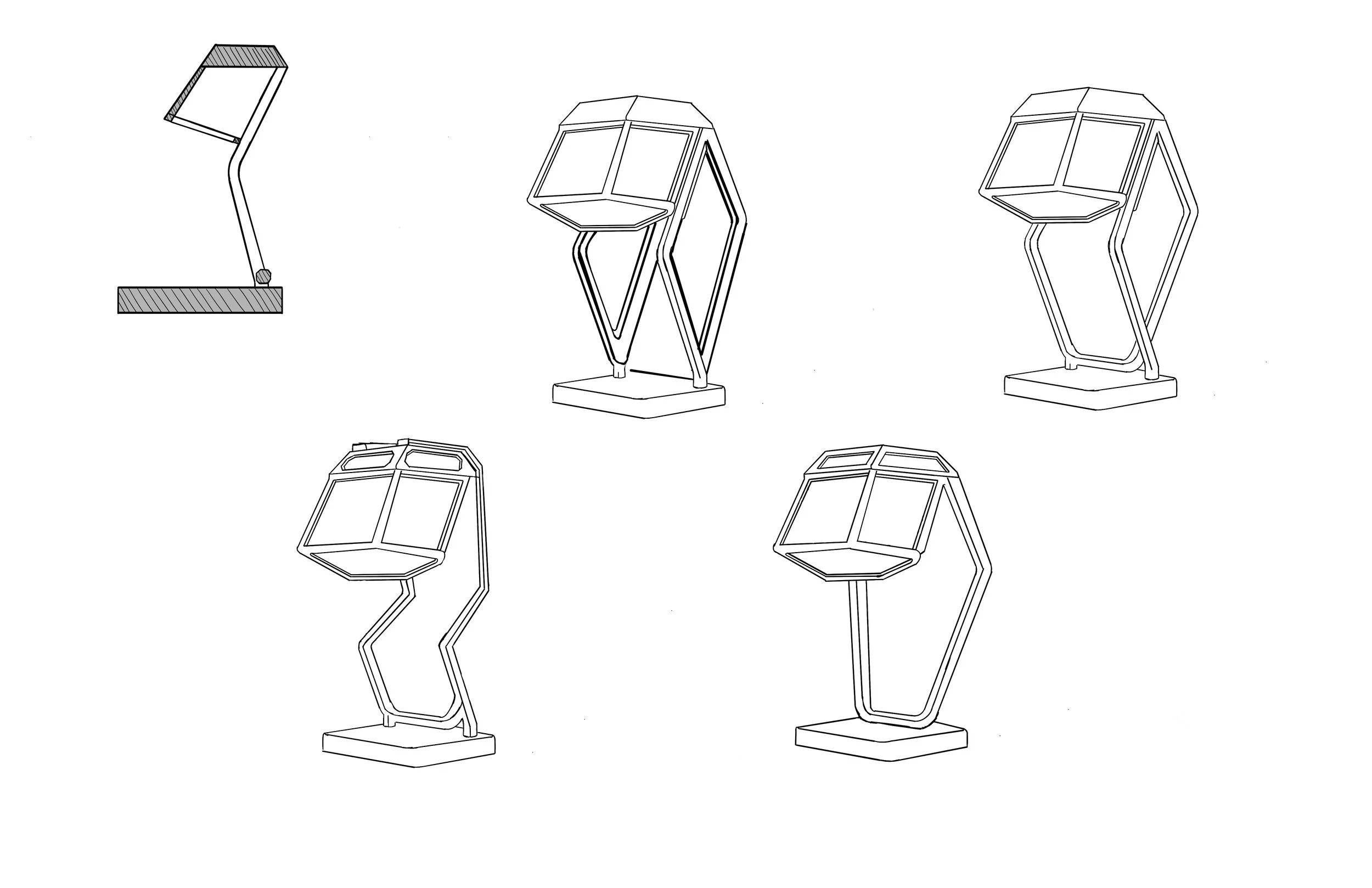

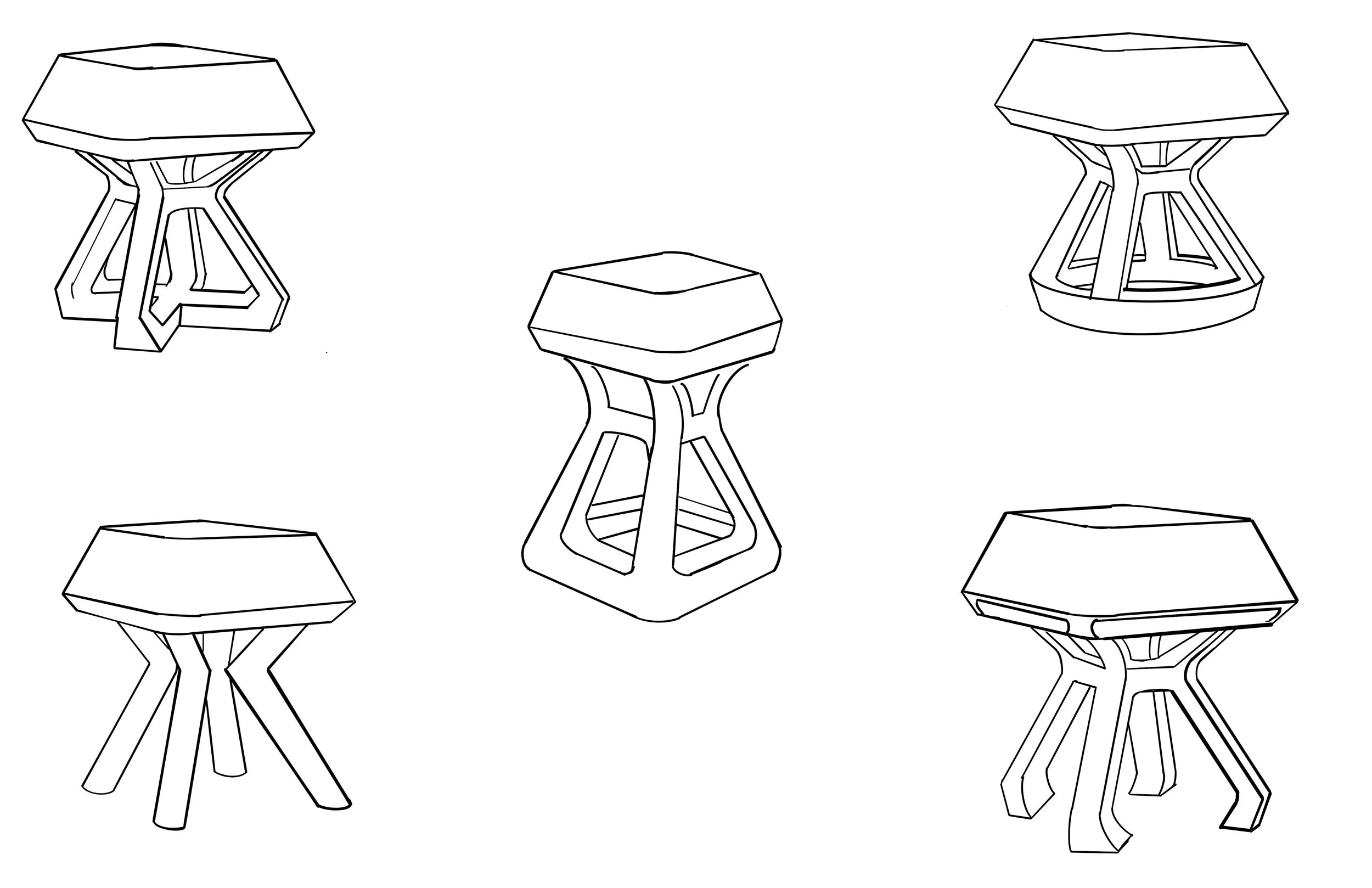

Focused Sketching

Focused Sketching & Direction Selection

Chose four key directions to refine overall form and function

Explored internal architecture to ensure space for components

Iterated silhouettes while balancing structure, layout, and usability

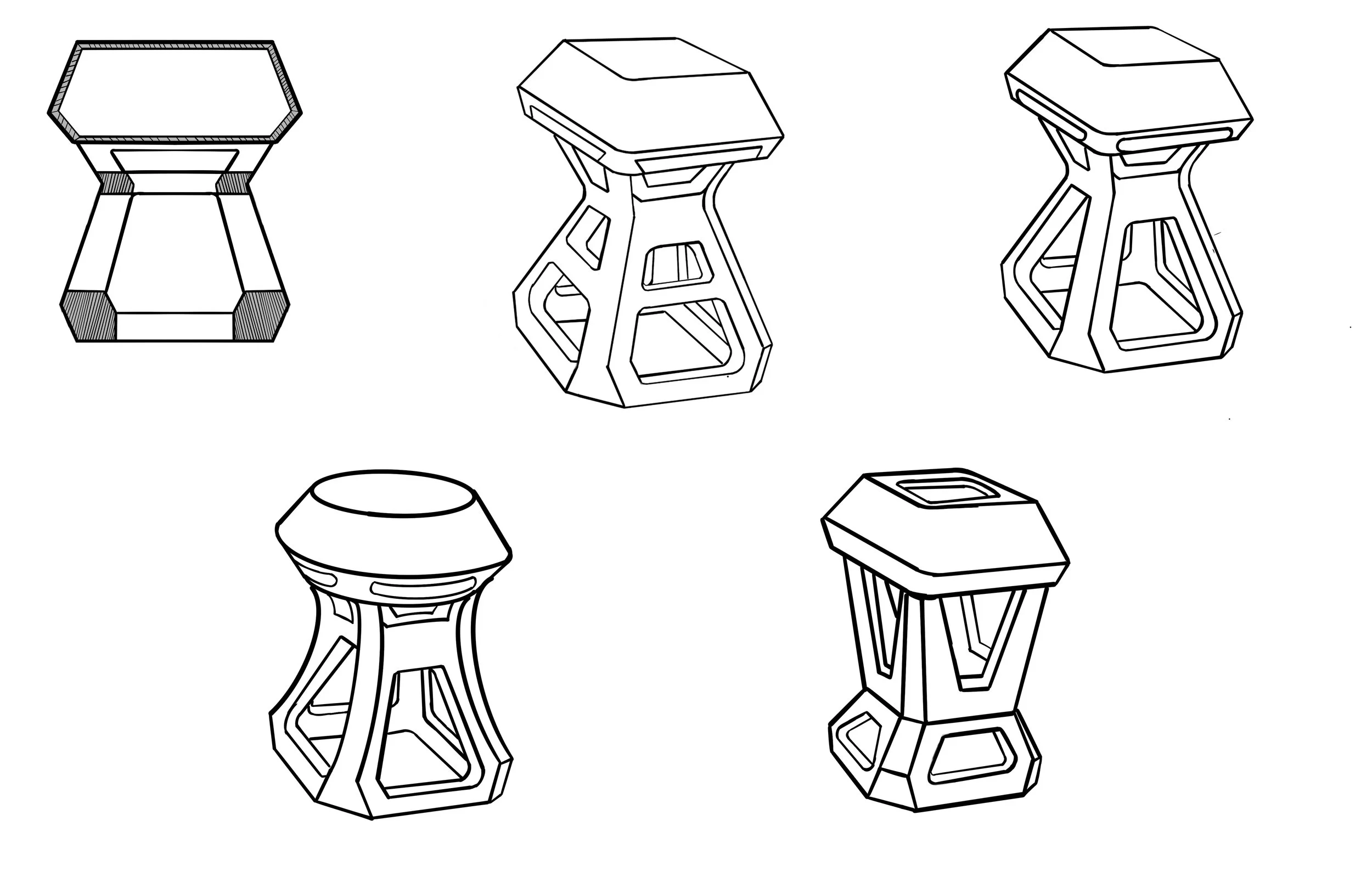

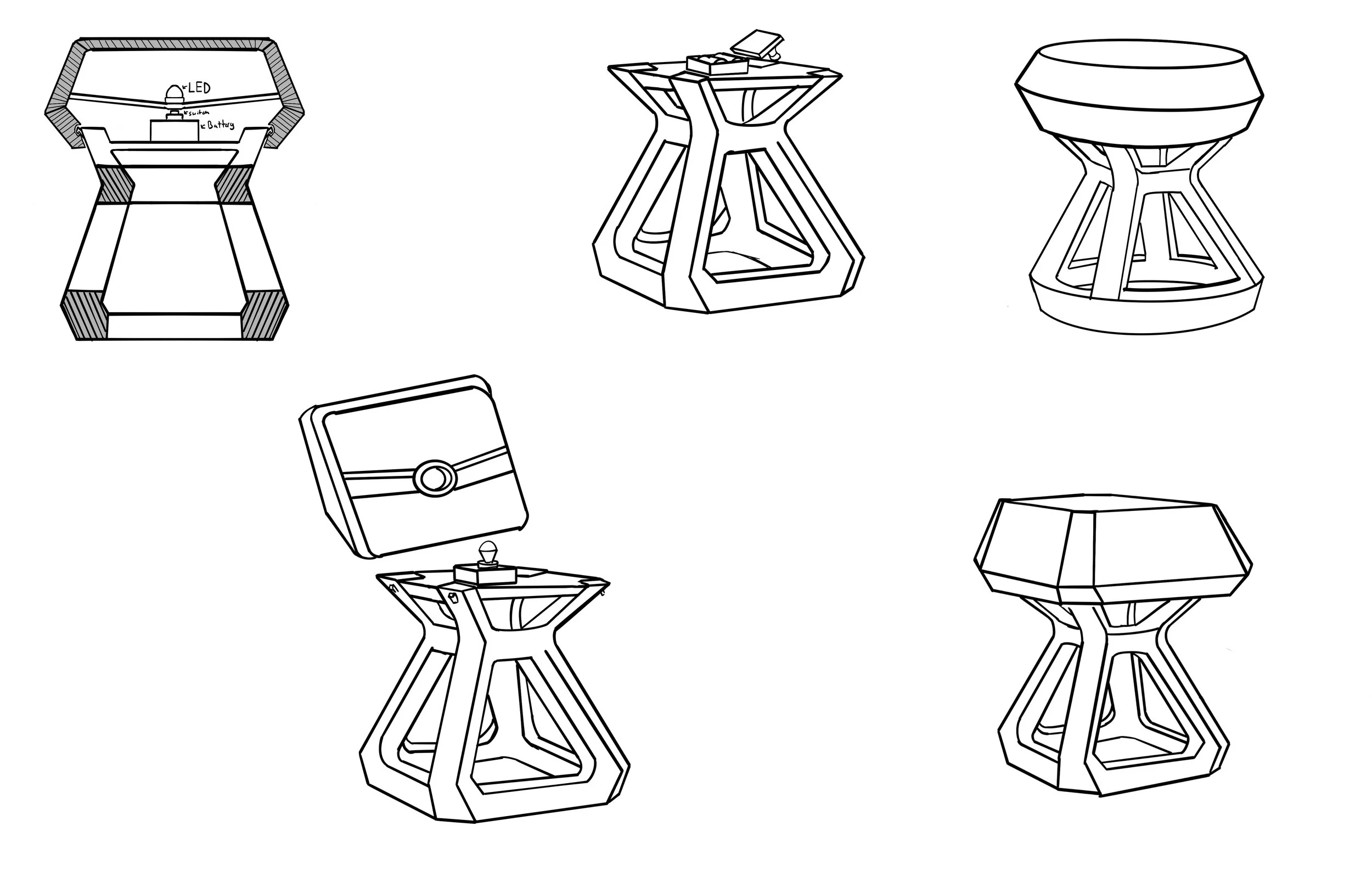

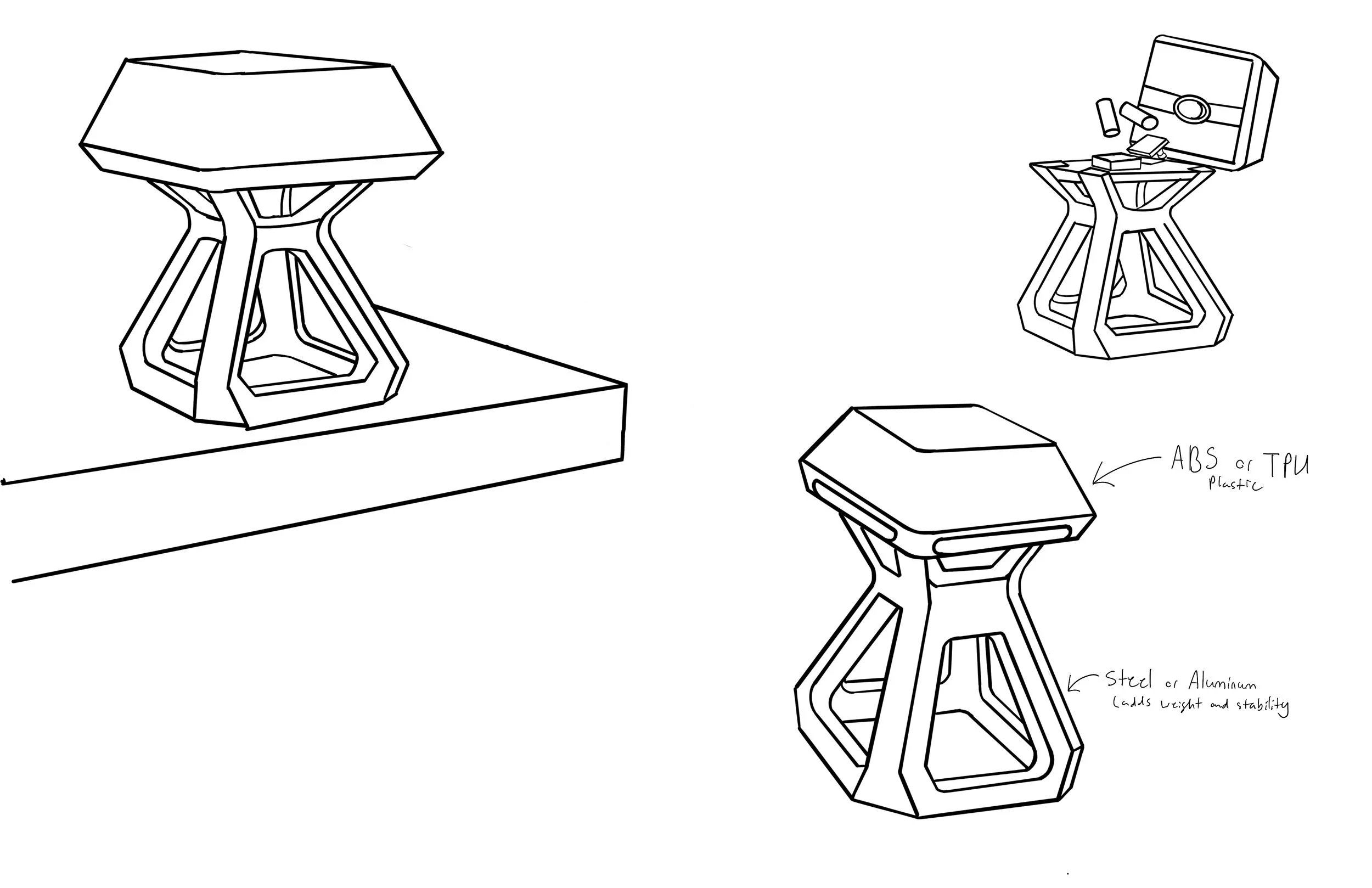

Final Direction Iterations

Finalized Form with Component + Material Layout

Inspired by a mechanical keycap—lamp activates by pressing the top down like a switch.

Selected final direction and refined form through targeted iterations

Laid out all internal components for clean, efficient integration

Defined materials: ABS top, steel base, silicone bottom for grip

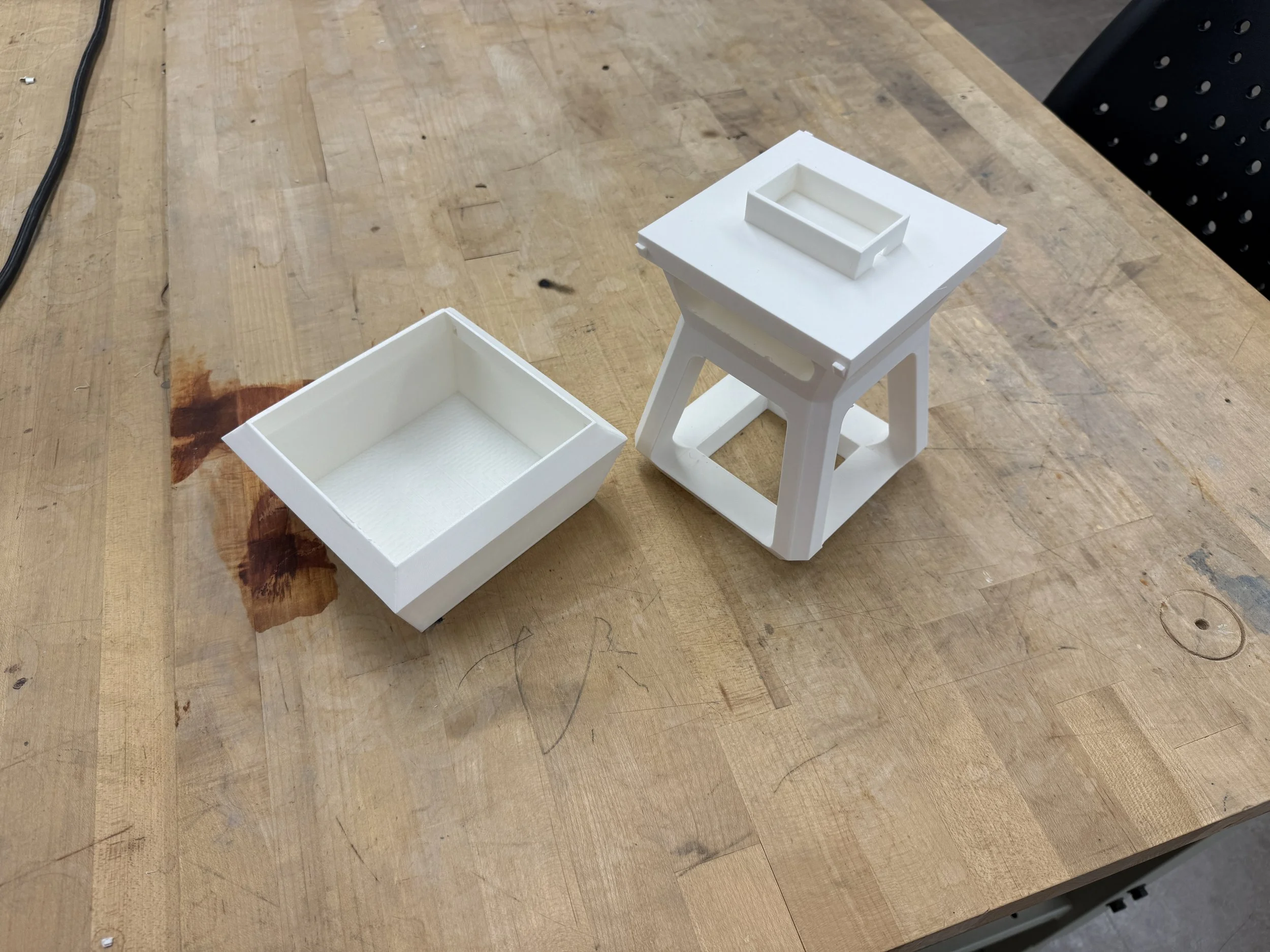

Paper Board Models with Final Direction

Early Paperboard Prototypes

Built paperboard models to test overall shape and volume

Helped evaluate early proportions, footprint, and general feel

Revealed need to refine height, width, and frame dimensions

Guided decisions on final scale before moving into CAD

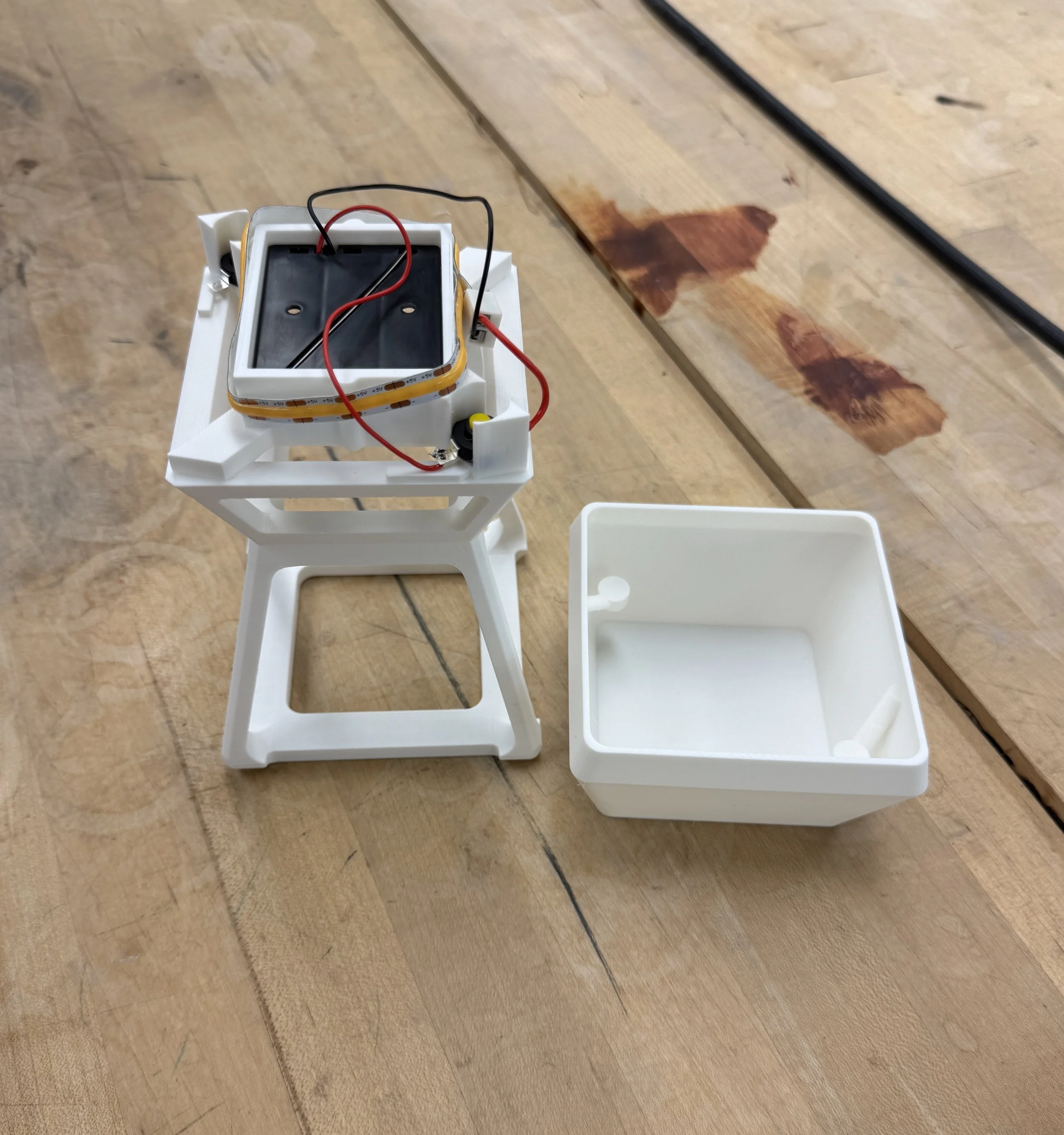

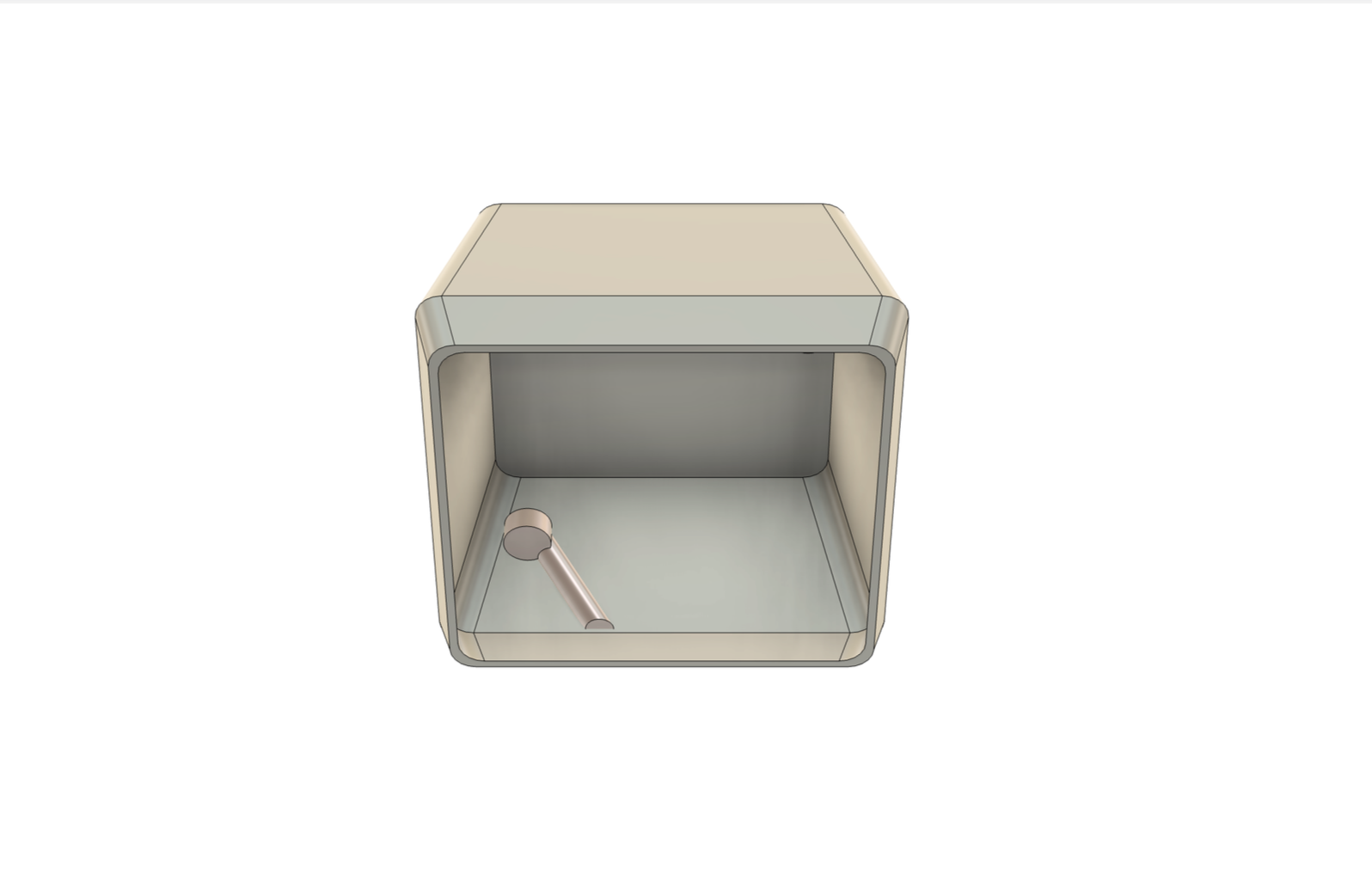

First CAD Model and 3D Print

Initial Digital Model to Physical Test

Built first full CAD model and printed an early prototype

Identified areas to thin the form for cleaner proportions

Found clicking-down mechanism issues needing redesign and alignment

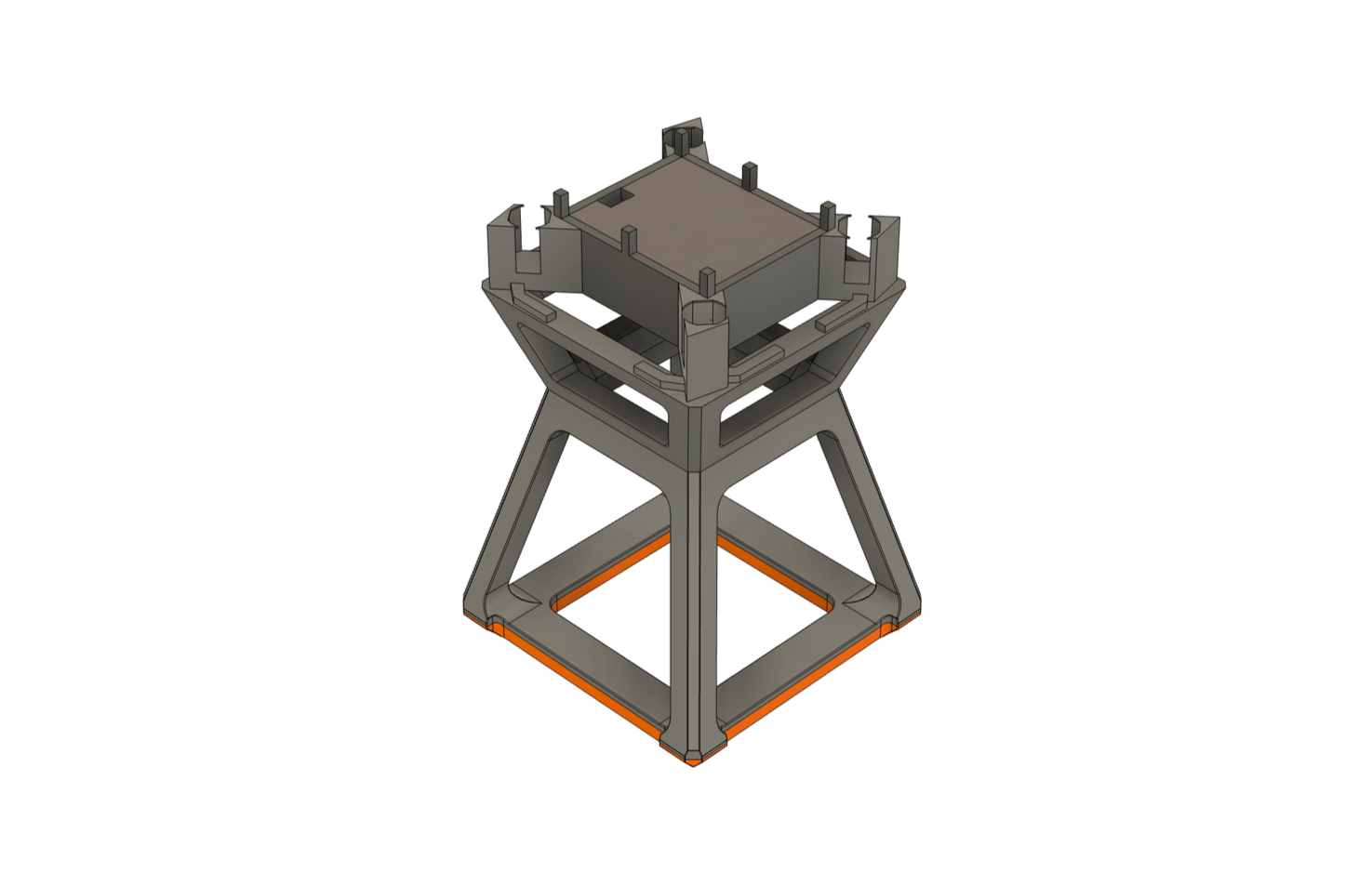

Refined CAD Model and 3D Print

Second CAD Model & Mechanism Revision

Corrected proportions and refined surfaces for final geometry

Clicking system worked but required redesign for manufacturability

Updated component layout to support realistic production methods

Final 3D Model

Production-Ready CAD Model

Locked in colors, materials, and final proportion adjustments

Completed production-ready click system within refined internal layout

Final CAD reflects finished design intent and mechanical function

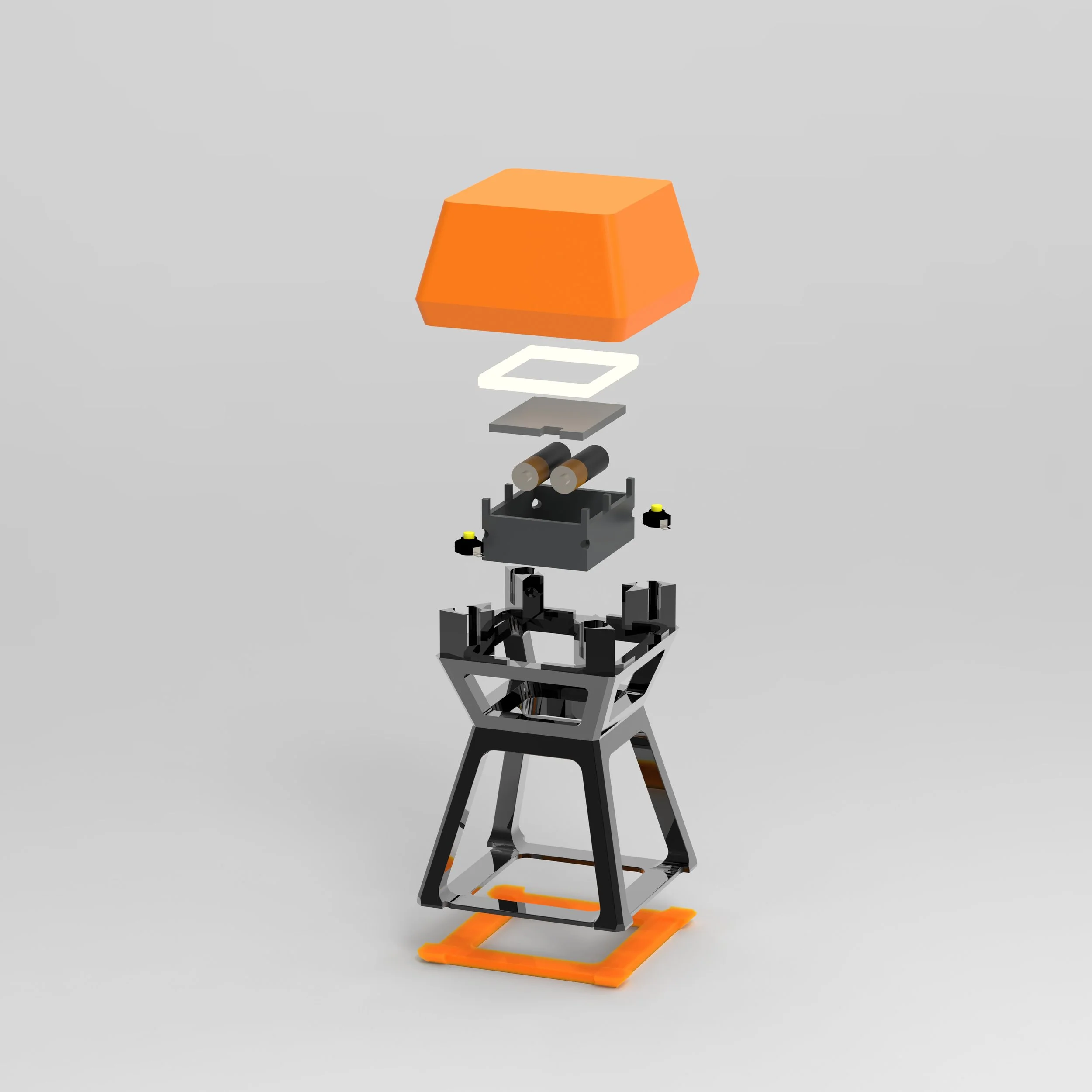

Renders and Exploded View

Final Renders & Exploded Architecture

Produced context renders on desk and nightstand with lights on/off

Showcased ambient lighting effect and final visual presence

Created exploded view to reveal internal components and structure